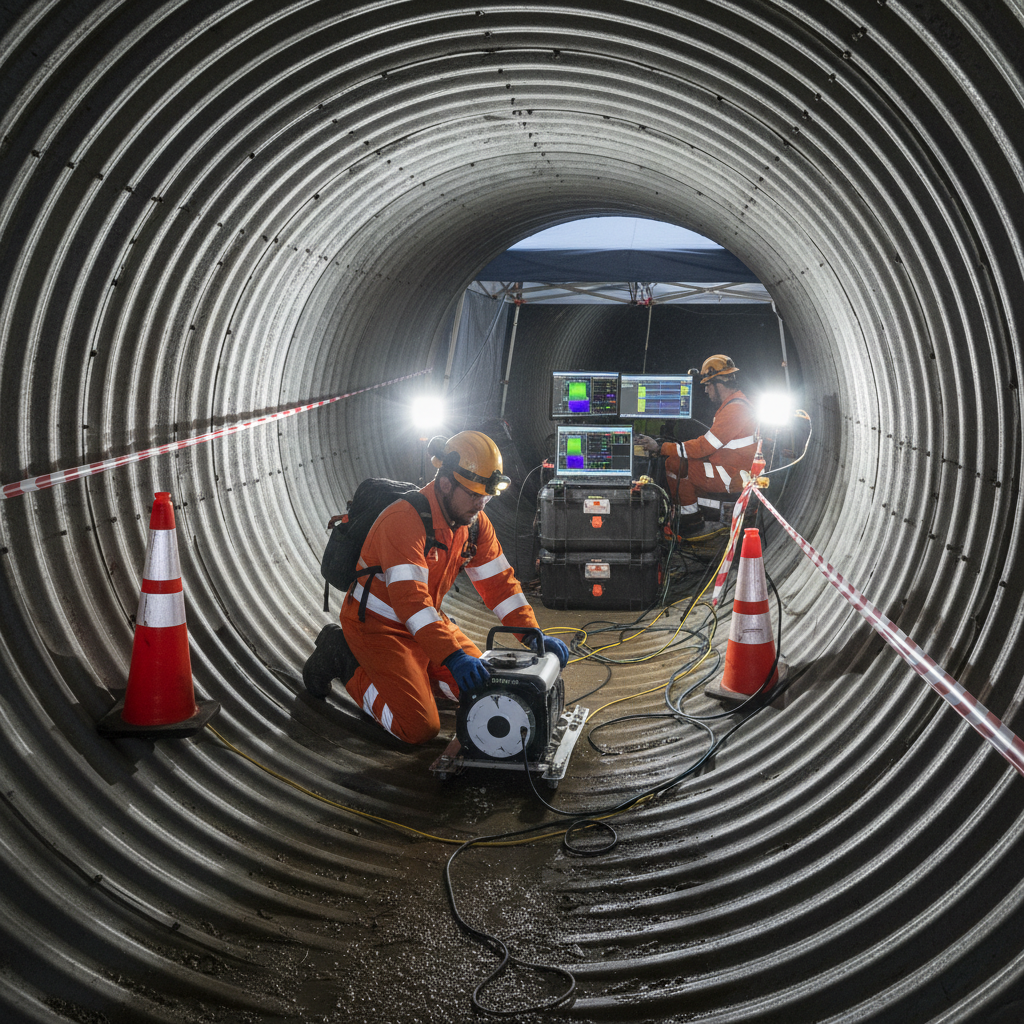

Multi-Channel Analysis Surface Wave (MASW) Survey

Our MASW survey employs trenchless geophysical technology, providing an efficient alternative to traditional drilling and trenching for site investigation. This non-destructive method is particularly advantageous in urban areas, minimising surface disruption while delivering detailed insights into subsurface conditions.

MASW measures seismic surface waves mainly from 2 types of seismic sources

- Active Mode:

- Source generated by hammers or weight droppers on ground

- Survey depth is within 30m

- Passive Mode:

- Source obtained by ”ambient noise” – such as trucks or construction activities

- Survey depth from 30m to 120m

Applications of the MASW Survey:

- Identification of subsurface layers

- Location of deep obstructions

- 3D visualization of boulders and rock head profiles

- Void detection beneath high water levels

Refer to the link below for the MASW Brochure

https://www.waterland.com.hk/wp-content/uploads/MASW-Seismic-Survey.pdf

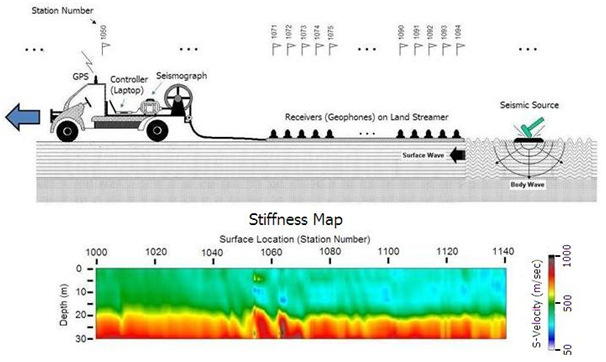

Borehole PS Suspension Logging Geophysical Survey

The PS Logger is a tool used to measure how fast seismic waves (P and S waves) travel through the ground in a borehole (a narrow, deep hole drilled into the earth). These measurements are important because they help engineers understand the stiffness of soil and rock, particularly for projects such as offshore wind farms or large-scale construction projects.

In borehole PS suspension logging, a fluid-filled borehole is used to transmit seismic waves generated by a PS Logger tool. The tool’s dipole source creates low-frequency waves, and two receivers measure the travel times of P- and S-waves through the surrounding soil or rock. These wave speeds are used to calculate soil stiffness (Gmax) and other material properties critical for geotechnical projects.

The importance of the PS logger works well in soft soil and underwater environments, where other methods might fail.

Calculates Gmax, which helps identify how soil or rock reacts to vibrations or waves.

Refer to the link below for the PS Suspension Logging Brochure

https://www.waterland.com.hk/wp-content/uploads/brochure_PS-logging-v1.pdf

Multi-convey 3D radar

Multi‑Convey 3D Radar is an advanced ground‑penetrating radar (GPR) service designed to capture high‑resolution, three‑dimensional images of subsurface features. Using multiple radar channels and rapid data collection, this system provides detailed mapping of underground utilities, structures, voids, and geological conditions. The technology delivers accurate depth information and clear visualisation of complex subsurface environments, supporting safer planning, excavation, and engineering design.

Key Benefits

- Provides high‑resolution, 3D subsurface imaging for accurate mapping

- Reduces excavation risk by identifying underground utilities, voids, and structures

- Improves project planning and safety with reliable, data‑rich results

- Increases survey efficiency by covering large areas quickly

- Minimizes the need for intrusive or destructive investigation methods

Key Features

- Multi‑channel antenna system for detailed, three‑dimensional data capture

- Rapid data acquisition with high spatial accuracy

- Detects both shallow and deeper subsurface anomalies

- Suitable for a wide range of environments, including construction, engineering, and utility projects

- Produces clear visual outputs for easy interpretation and reporting

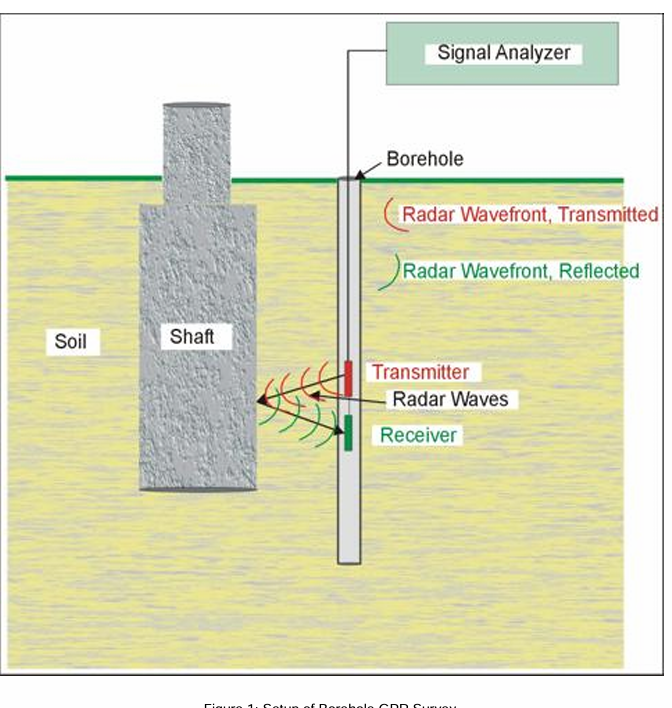

Borehole GPR

Borehole Radar uses a ground‑penetrating radar antenna inside a borehole to detect reflections from subsurface structures, helping determine the depth and shape of foundations. The method works by transmitting radar waves into the surrounding ground and recording reflections from materials with different dielectric properties. It operates in reflection mode, with penetration depth depending on frequency and ground conductivity—lower frequencies reach deeper but provide lower resolution.

In foundation‑depth investigations, borehole radar records reflections from the foundation until its base is reached, where reflections cease except for those from natural geological layers. This change in signal indicates the foundation bottom. The method requires a PVC‑cased borehole and is limited by the electrical conductivity of surrounding soils, with penetration up to about 10 m in resistive ground and much less in conductive materials, making close borehole placement important.

UXO Survey

UXO (Unexploded Ordnance) surveying is a specialised safety service designed to identify and assess potential explosive hazards left behind from historical military activities or previous land use. Using advanced detection technologies, our team locates buried metallic objects and evaluates their risk, ensuring the site is safe for construction, excavation, and development. This service provides clients with confidence and compliance, supporting safe and efficient project planning.

UXO surveys provide a reliable and efficient way to identify potential unexploded ordnance hazards before construction or ground disturbance begins. Using advanced geophysical detection methods, they help ensure site safety, reduce project risk, and prevent costly delays. Key benefits include improved worker safety, compliance with regulatory requirements, accurate detection of buried metallic objects, and greater confidence in project planning and development.